- Totally cGMP compact design available in plain water jacketed &flame proof model.

- Improving the bulk density of material.

- It improves uniform mixing of material.

- It does achieve better granulation of sieves analysis.

- It produces uniform particle size range of granules.

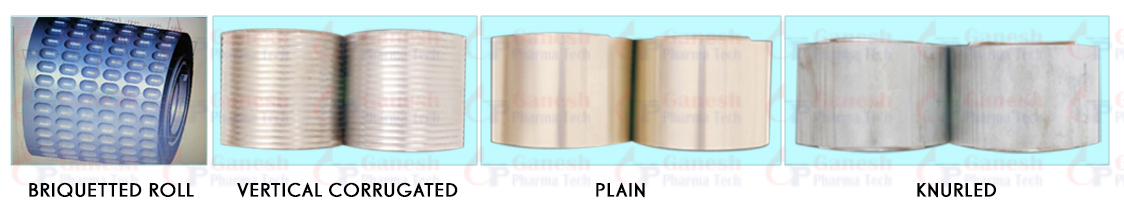

- Various types of roll available to achieve maximum bulk density of output.

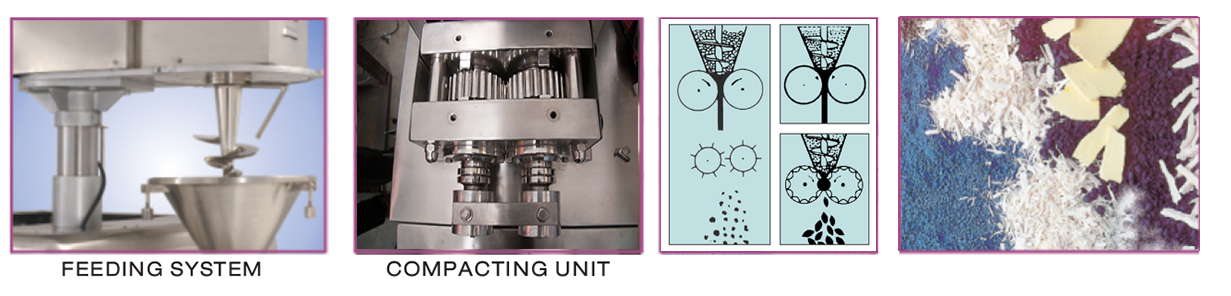

- Specially designed feeding system consisting of hopper pre-densifier & variable speed drive unit.

- Feeding unit can be hydraulically lifted by hydraulic pump for ease of cleaning.

- Specially designed rollers to prevent powder sticking on the roll.

- Pre-compression chamber guides the powder without any slippage or leakage.

- To prevent major accident the rolls are designed to rotate in reverse & forward direction while cleaning process takes place.

- Special limit switch is provided to prevent major accident.

- OEL – Level 5 for Operator Safety.

- Main roll drive is designed with twin shaft gear box coupled with coupling to protect roll drive unit therefore perfectly synchronizing the roll with a constant torque.

Other Features:

- Saves quality of active materials: Dry Granulation Process saves the quality of active raw-materials at its best. Material remains safe from Oxidation / Reduction / Temperature / Atmospheric hygroscopic absorbency.

- Saves installation of related equipments & spaces: Does not require drying equipments on account of Compaction Process. So Drier Equipments & Spaces are saved.

- Saves power installations & consumption : Power requirements are only 7 H.P. compared to account of compaction to more than 50 H.P. for Fluid Bed Drier.

- Power Conservation Comparative Study for Processing of 500 Kgs. granules proves : Wet Granulation (246.5 KW/HR.) – roller compactor machine (34 KW. HR. )= SAVING (34 KW. HR. )

- Saves man power:Wet Granulation (22.5 man./ hr.) – ROLLER COMPACTOR MACHINE (8 man./ hr.)= SAVING(14.5 Kw.HR.)

- Increase production capacity by 1 to 30Million of tablets :Serrations (60) X Rpm (5)XWeight(3) XMinute (60) XWork Time (6) = Compacts/Granules Output (324 Kgs.)

- Easy & perfect cleaning on change over: Machine Design permits perfect cleaning in just 15 minutes. Machine Design permits cleaning with water hose pipe & soap water.

- Reduces Industrial hazards : Alternative production process requires use of Non – Aqueous Binders that causes industrial hazards of fire, cost and human damages which is saved on account of dry Granulation processing.

- Dry granulation made productive & efficient: Alternative Slugging Equipments have Cumbersome Operation, Less Efficient Slugging and Low Productivity.

- Ready formulation suggestions: Backed by actual involvement in manufacture of various Formulations from one of the Directors of the company.

Specifications :

| MODEL | GPT – 200 / 50 | GPT – 200 / 75 | GPT – 200 / 100 | GPT – 200 / 150 | GPT – 200 / 200 |

| Output* | 20 to 40 Kgs/hour | 30 to 80 kg. | 50 to 150 kgs./hour | 75 to 250 kgs./hour | 128 to 350 kgs./hour |

| Roll Size | 200 mm Dia x 50 mm(w) | 200 mm Dia x 75 mm (w) | 200 mm Dia x 100 mm (w) | 200 mm Dia x 150 mm (w) | 200 mm Dia x 200 mm (w) |

| Roll Speed (Step pulley drive) | 5 to 20 RPM | 5 to 20 RPM | 5 to 20 RPM | 5 to 20 RPM | 5 to 20 RPM |

| Feed screw Speed | 10 to 50 RPM | 10 to 50 RPM | 10 to 50 RPM | 10 to 50 RPM | 10 to 50 RPM |

| Roll drive Motor | 5 HP, 960 RPM,440 V, 3 Phase, 50 Hz | 5 HP, 960 RPM,440 V, 3 Phase, 50 Hz | 5 HP, 960 RPM,440 V, 3 Phase, 50 Hz | 10 HP, 960 RPM,440 V, 3 Phase, 50 Hz | |

| Feed screw drive Motor | 2 HP, 1440 RPM,440 V, 3 Phase, 50 Hz | 2 HP, 1440 RPM,440 V, 3 Phase, 50 Hz | 2 HP, 1440 RPM,440 V, 3 Phase, 50 Hz | 3 HP, 1440 RPM,440 V, 3 Phase, 50 Hz | |

| Overall Dimension (In mm) | 1160 (W) * 1160 (B) * 2032 (H) | 1160 (W) * 1160 (B) * 2032 (H) | 1160 (W) * 1160 (B) * 2032 (H) | 1160 (W) * 1160 (B) * 2032 (H) | |

| Net Weight | 1000kgs. | 1200 kgs. | 1500 kgs. | 2500 kgs. | 3000 kgs. |

*Depending upon the characteristics of material.

*Output based on practical experience

Note : Specifications of the Machineries are subject to change without any prior notice

| Suggested Formulas For Direct Compaction & Compression to Tablets. | |||||||

| NO. | NAME OF PRODUCTS | ACTIVE | MCCP | STARCH | MG. ST. | TALC | OTHER |

| 1. | ANALGIN & COMBINATIONS | 10 KGS. | 0.5 KG. | 0.3 KG. | 0.1 KG. | ———- | |

| 2. | ERYTHROMYSIN ST. / ESTOLATE | 10 KGS. | 1.0 KG. | 0.3 KG. | 0.1 KG. | 0.1 KG. | ———- |

| 3. | GRISEOFULVIN TAB. | 10 KGS. | 1.5 KG. | 1.5 KG. | 0.1 KG. | 0.1 KG. | 0.2 KG. S.S.G. |

| 4. | IBUPROFEN TAB. | 10 KGS. | 1.0 KG. | 0.4 KG. | ———- | 0.1 KG. | 0.1 KG. AEROSIL |

| 5. | DI – IODOHYDROXYQUINOLENE | 10 KGS. | 1.5 KG. | 1.5 KG. | 0.1 KG. | 0.1 KG. | ———- |

| 6. | IODOCHLOROHYDROXYQUINOLENE | 10 KGS. | 1.5 KG. | 1.5 KG. | 0.1 KG. | 0.1 KG. | ———- |

| 7. | CHLOROPROMZINE HYDROCHLORIDE TAB. | 10 KGS. | 4.0 KG. | 5.0 KG. | 0.4 KG. | 0.4 KG. | 8.0 KG. D. C. P. |

| 8. | ETHAMBUTAZONE TAB. | 10 KGS. | 1.5 KG. | 0.5 KG. | 0.1 KG. | 0.1 KG. | 0.1 KG. GUAR GUM |

| 9. | OXYPHENEBUTAZONE TAB. | 10 KGS. | 1.0 KG. | 1.0 KG. | 0.1 KG. | 0.1 KG. | 0.1 KG. S. S. G. |

| 10. | PHENYLBUTAZONE TAB. | 10 KGS. | 1.0 KG. | 1.0 KG. | 0.1 KG. | 0.1 KG. | 0.1 KG. S. S. G. |

| 11. | RANITIDINE TAB. | 10 KGS. | 2.0 KG. | 1.0 KG. | 0.15 KG. | 0.15 KG. | 2.0 KG. DCP/LACTOSE |

| 12. | MEBENDAZOLE TAB. | 10 KGS. | 2.0 KG. | 1.0 KG. | 0.15 KG. | 0.15 KG. | 2.0 KG. D. C. P. |

| 13. | CHLOROQUINE PHOSPHATE | 10 KGS. | 1.0 KG. | 1.0 KG. | 0.1 KG. | 0.1 KG. | 0.1 KG. GUAR GUM |

| 14. | BASE GRANULES/POTENT MEDICINE | 10 KGS. | 4.0 KG. | 2.0 KG. | 0.1 KG. | 0.1 KG. | 4.0 KG. D. C. P. |

| 15. | MULTIVITAMINS TAB. | 10 KGS. | 2.0 KG. | 1.0 KG. | 0.1 KG. | 0.1 KG. | 2.0 KG. LACTOSE |

| 16. | ASPIRIN & COMBINATION TAB. | 10 KGS. | 1.0 KG. | 1.0 KG. | ———- | ———- | ———- |

| 17. | AMPICILLIN & OTHER DRY SYRUP | 10 KGS. | 2.0 KG. | ———- | ———- | ———- | 0.1 KG. AEROSIL |

| 18. | NORFLOXACIN TAB. | 10 KGS. | 2.0 KG. | 2.0 KG. | 0.15 KG. | 0.15 KG. | 0.1 KG. S. S. G. |

| 19. | CIPROFLOXACIN TAB. | 10 KGS. | 2.0 KG. | 2.0 KG. | 0.15 KG. | 0.15 KG. | 0.1 KG. S. S. G. |

| 20. | RIPHAMPICIN & COMBINATION | 10 KGS. | 2.0 KG. | 1.0 KG. | 0.2 KG. | 0.2 KG. | ———- |

| 21. | ANTIBIOTIC KID & DISPERSIBLE | 10 KGS. | 2.0 KG. | 1.0 KG. | 0.2 KG. | 0.2 KG. | ———- |

| GUM ACACIA | 1.1 KG. PUL. SUGAR | ||||||

| 23. | IBU – PARA TAB. 4.0 KGS. + | 3.25 KGS. | 1.0 KG. | 0.5 KG. | ————- | 0.2 KG. | 1.0 KG. PUL. SUGAR |

| 24. | ALUMINIUM HYDROXIDE TAB. | 10 KGS. | 1.5 KG. | (SUGAR) SACHARIN, COLOUR. 3-5% Water should be | |||

| Uniformly mixed to help Better Compaction till no Sticking on Roll Surface. | |||||||