- Totally cGMP Compact design availably in plain, water jacketed & Flame proof model.

- It’s improving the bulk density of material.

- It’s improves uniform mixing of material.

- It’s achieve better granulation of sieves analysis.

- It’s produce uniform particle size range of granules.

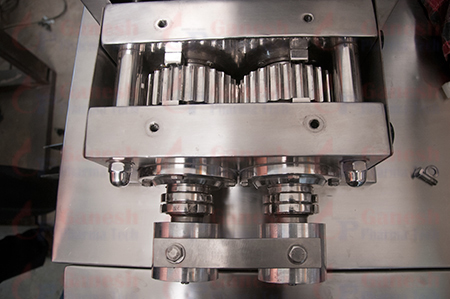

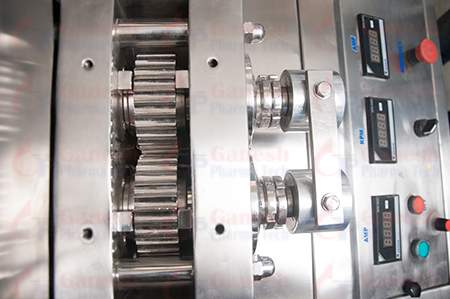

- Various types of roll available to achieve maximum bulk density of output.

- Specially designed feeding system consisting of hopper pre-densifer& variable speed drive unit.

- Feeding unit can hydraulically lift by hydraulic pump for easy cleaning.

- Specially design provide in the roller to prevent powder sticking on the roll.

- Pre-compression chamber guides the powder without any slippage or leakage.

- To prevent major accident the roll is designed to rotate reverse & forward when cleaning. Specially limit switch is provided to prevent major accident.

- Main roll drive is design with twin shaft gear box coupled with coupling to protect roll drive unit therefore perfectly synchronizing the roll with a constant torque.

Specifications :

| Model | GTP-RC-35 |

| Output | 2-5 Kgs./Hr.* |

| Roll size | Ø 100 mm x 35 mm |

| Roll speed (through AC Drive )) | 2 to 25 RPM |

| Feed screw speed(through AC Drive ) | 5 to 60 RPM |

| Roll drive Motor | 3Hp/960RPM/3 Ph. |

| Feed screw driver motor | 1 HP / 1440 RPM / 3 Ph. |

Output depending upon the material characteristics & its nature.

Water Jacketing System to be used considering the below points:

- Water should enter in the water-jacketing system with gravitational force and the inlet of water must be parallel to it.

- The force of inlet water should not be high, it must be normal.

- The volume of inlet and outlet should be equal it means if outlet volume is one liter in 10 min. then inlet volume should not increase than 1 liter in 10 minutes.

- Force of inlet water should be controlled through appropriate valve between inlet of water- jacketing system and your source of water supply.

- Outlet water from water-jacketing system must not be re-circulated to avoid backpressure to the seals and it should go to drain only.

- Always supply raw water to the water-jacketing system as it is require maintaining the temperature between two rolls while compaction.

- Don’t supply chilled water as it will condensed to rolls and shafts because the area, where the machine will be installed, will be air conditioned and also Rh must be maintained.

- If above points are considered and implemented during the installation of the machine, the problem of leakage from the water-jacketing system should not occur.