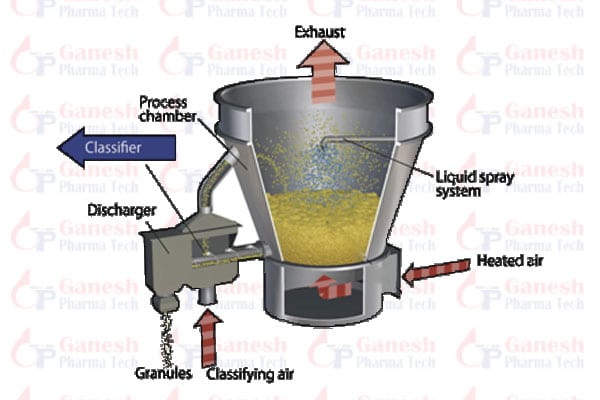

Our Fluid Bed Dryers offer a custom solution to drying of wet granules, crystalline or coarse materials. It utilizes the principle of passing the hot air at a high velocity through the bed of the material to be dried thus causing it to fluidize.

Fluidized bed technique is most effectively utilized in a number of heat and mass transfer applications like Drying, Cooling, Calcinations, Roasting, Carbonization, Reaction, Sterilization, and much more.

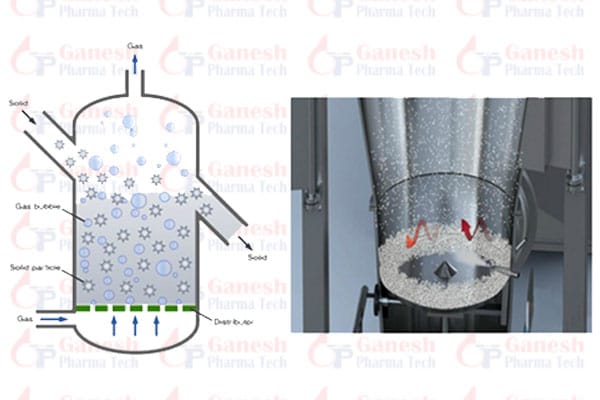

Fluid means a liquid. A substance is said to be fluidized when it starts behaving like a liquid. When a determined quantity of air is passed below a perforated bed, carrying the substance to be dried, say PVC, the material starts bubbling and it behaves like a fluid. Much depends upon the substance, its moisture content, size of perforations, and airflow.

When the air velocity is low, the bed of solids remains still. As the air velocity increases, the particles on the upper part of the static bed begin to move and separate from one another. The particulate bed is expanded and the movement of particles becomes an active form of a mixture of air and particles. This gas solid mixture is called “Fluidized Bed”.

When the air velocity through the fluidized bed is increased further, the particles bubble more and more vigorously some of the particles begin to gradually fly-off. When the air velocity exceeds the terminal velocity of the particles all of the particles may be blown-off resulting in “Carry Over”.